Ok first off, thanks for the kudos, and letting me know you were going to post that

Second, Rotocasting is an art in itself. You can build a machine in any way you can. Wood, Aluminum, Steel... But the key is, MATH.

I dont claim to be an expert, but I was mentored by one and I am very happy I was or I would have made some very costly mistakes.

Some of you ask "why". One reason is this, If I were to make my blasters simply by pouring the resin in the mold , wait, then pull it out, its too heavy to troop in, plus its costly. Resin is not cheap, and as of late the cost just went up.

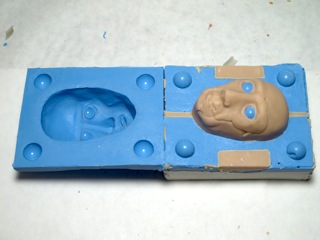

I took my master and made a two part silicone mold which is held in place by a exoskeleton (or fiberglass jacket). I pour the resin in, turn on the machine and watch it go. the resin coats the inside of the mold until its hard. After you have a hallow piece which is light to carry, and light on the wallet. Another benefit is that you can add electronics to it, which you cant really do very well if it was solid. If you have trooped a parade like i have, even the lightest prop gets heavy after a while.

The most difficult part about building a machine is weight distribution. For each mold you need to find the center mass, and kind of go from there. The rotocast machine I really want is 3 grand, that kind of scared me to make my own lol. But by this time, had I bought it, It would have paid for itself a few months ago :-/

The great thing about the one I want, is that is has variable speed on BOTH frames.

Thats the key. Your outside frame can spin as fast or slow as you want, but how are you going to control the inner frame? If you go to fast, there wont be enough coverage, if you go to slow, the resin will harden quickly and make the walls uneven. When I first was dialing in my machine, I scrapped a few parts because my mold wasnt doing a complete 360 turn, which i thought it was!

How I changed the speed was changing one of my gears that controlled the inner frame. When it comes to making a helmet, im hoping that changed aids that as well.

I very much want to sculpt a cylon helmet and rotocast it. I plan on getting a helmet from CORA soon so that once its together, I can use it as a reference, with his permission of course.

Help control your re-caster population. Have them spayed and destroyed

The cylon rifles, I know they are not rotocasted originally, but I still think it would be cool to do one. I want to someday be a part of the army here that has something to offer to help us grow. I AM an arms dealer after all

Anyway, I hope that gives some insight, I left A LOT out because I cant cram a years worth of learning in one post lol!

Here is what my mold looks like opened up

cheers